Bambu looks at Bamboo Fashion

- Bambú Magazine

- May 1, 2019

- 3 min read

Updated: May 2, 2019

By Nicole Weber

With the advancement in technology, more and more ways to reduce our impact will be discovered. According to Moto Suzuki, the owner of Japanese sustainable clothing brand Coveross, the best way to lessen our footprint is to reuse materials.

“The resources of the earth are limited; population grows and the living standards of the underdeveloped countries go up, a crisis will occur not online in the fashion industry but in all industries,” he said.

For now, can the development of more sustainable plant based fabrics be enough?

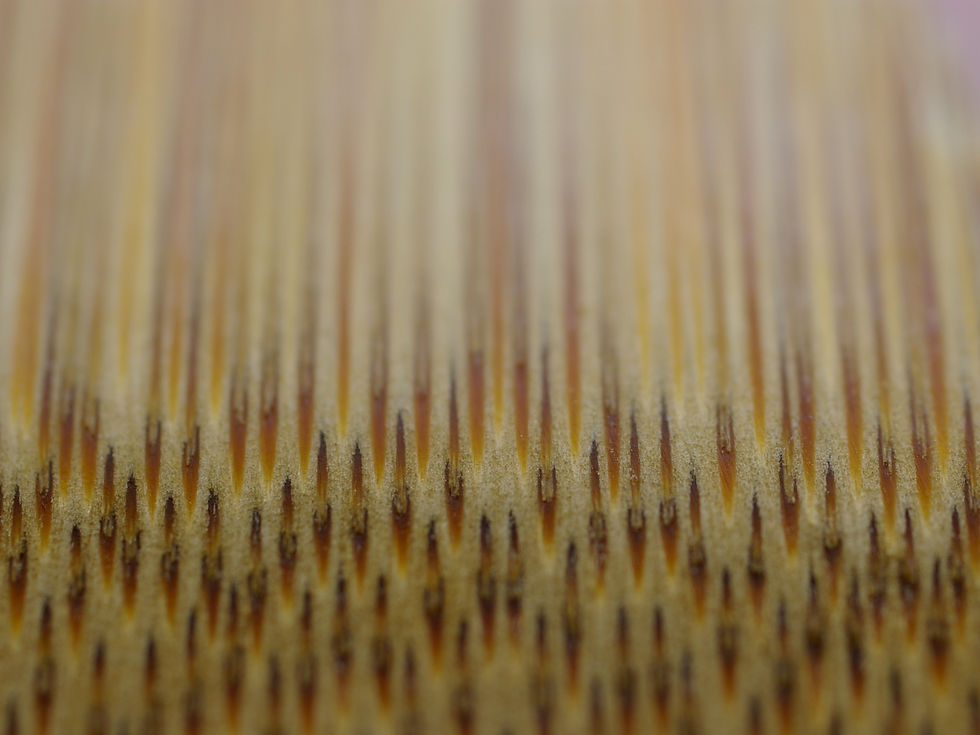

Bamboo is one of the fastest growing plants there are, so it would make sense that it’s becoming a more popular material to work with. It only needs a small amount of water and only 10% of land to yield the same amount as cotton.

There are loads of advantages to bamboo materials, not only for producers but for the consumers as well. They can be easily grown without using pesticides, and they can be grown anywhere, so farming it is a lot simpler.

The fabric itself is also a lot softer, which makes it better for clothing than man made nylon, according to David Gordon, who works for Bamboo Clothing, an online retailer based in the UK.

The difficulty lies with the manufacturing of bamboo. As they need to be broken down into its natural cellulose, it involves “a multi-phase bleaching, using caustic soda. However, there are new developments coming all the time”.

Gordon says that it’s possible we may start seeing bamboo more in the high street. “Following on from the huge push for companies and individuals to become more environmentally aware, sustainable and to reduce the amount of waste, people are looking for more sustainable fashion,” he said.

The main disadvantage with the manufacturing of bamboo is the way in which the plant needs to be broken down into its natural cellulose. “There is a chemical process involved in this; part of the processing to fibre is a multi-phase bleaching, using caustic soda,” says Gordon. At the moment, there is no way to avoid this.

At the same time, chemicals are needed in the viscose process, to break down wood chips into pulp. “The wood pulp is treated and purified using carbon disulphide and a sodium hydroxide solution and the by-product created from this process can be recovered and re-used for energy production. Before being transformed into fibres, the solution is bleached,” he said.

In an article found in Cariloha, a blog about Bamboo, Scott Brady says that “Whether you are talking about a shirt or pants, or bed sheets or towels, bamboo will outlast cotton in keeping shape, strength, and durability three times over when cared for properly.”

“It is so versatile and can be used and made into almost anything, from flooring and paper to clothing and building materials. It’s soft and durable when woven, is extremely durable when made into clothes and boasts anti-bacterial and anti-fungal properties” said Rachel Kaplan in an article found in the National Geographic.

There are other methods of producing these fibres without the use of harmful chemicals but they tend to be more costly. “We are following any advancements in this very closely as we’re always looking for ways we can minimise our impact.”

Sadly, it seems we have not yet reached the point where we can fully source materials sustainably. There are still several negative impacts seen in the environment, and these are difficult to cut down on. On the other hand, it is an exciting time for sustainable designers, as they are the ones finding the solution to this world issue.

Comments